OUR CAPABILITY

CGL provide end-to-end service and expertise. Whether it is supporting your design team, producing mock-ups, feasibility studies, programming or technical assistance, we have the expertise to help you achieve your project goals for Rainscreen.

Overview

A new “joined-up” approach from design through to installation means we offer a very lean process where everything is fully considered from the outset, saving you time and money. We design it to be efficient to manufacture and we manufacture it to be safe, quick, and simple to install.

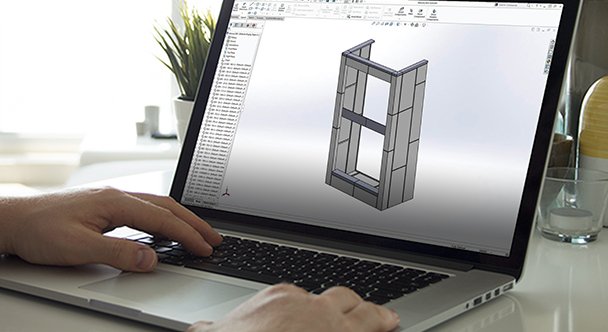

Design

Our design team will do the support structure calcs, develop the panel splits and sizes, assist with material selection and gauge, resolve difficult details around projections in the façade such as windows and porticos, and all while ensuring it is viable from a manufacturing and installation perspective.

Manufacture

With these extensive resources managed by our industry-leading Preactor™ production management software, we can deliver in large volumes quickly and reliably.

Install

UNRIVALLED MACHINERY & CAPABILITY

Our plant list across 3 facilities is extensive and reflects our continuous investment in the best equipment. This gives us excellent control over product quality and delivery times.